Hello everyone! Optical fiber is an important carrier of modern communication technology, and its physical material composition directly affects the transmission performance and application scenarios of optical fiber. Today gracyfiber is pleased to introduce to you in detail the basic structure of optical fiber and the two main material types – glass optical fiber and plastic optical fiber. We hope to help you better understand and choose the appropriate optical fiber to improve the bandwidth and reliability of the network. By understanding the characteristics of different optical fiber materials and their trade-offs in practical applications, I believe you will be able to inject new impetus into your digital transformation career.

Basic structure and materials of optical fiber

Let me introduce you to the basic structure and commonly used materials of optical fiber in detail:

Basic structure of optical fiber:

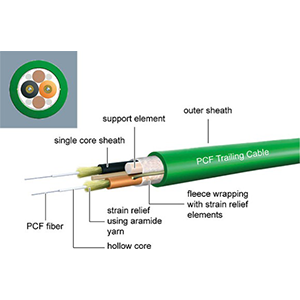

- The core structure of optical fiber consists of three main components: Core: the central area in which optical signals are transmitted. Cladding: The outer area surrounding the core is used to limit the propagation of optical signals within the core. Coating: The covering layer located outside the cladding to protect the optical fiber from mechanical and environmental damage.

Characteristics and comparisons of optical fiber materials:

Glass optical fiber: The material is usually high-purity silicate glass. It has good optical performance and transmission characteristics, and can achieve long-distance and low-loss optical transmission. The manufacturing process is complex and the cost is relatively high. It is sensitive to bending and mechanical impact and easy to break.

Plastic optical fiber: The material is usually polymer plastic, such as polymethylmethacrylate (PMMA). The manufacturing process is relatively simple and the cost is low. It has good resistance to bending and mechanical impact, making it tougher and more durable. Optical transmission performance is not as good as glass fiber, and distance and bandwidth are limited. It is more sensitive to changes in ambient temperature and humidity, and its reliability is worse than glass.

In general, glass optical fiber has better optical transmission performance and is suitable for high-speed, long-distance communication applications; while plastic optical fiber is more suitable for short-distance, low-cost, and easy-to-install application scenarios. sAccording to specific application requirements, appropriate optical fiber materials can be selected to build optical communication systems. In some special scenarios, optical fibers of two materials can also be used in combination to give full play to their respective advantages.

Glass optical fiber

Let me introduce in detail the manufacturing process, performance characteristics and application of glass fiber in high-speed broadband networks:

Manufacturing processes and types of glass optical fibers:

- Glass optical fibers are usually made of high-purity silicon-based glass materials and manufactured using a chemical vapor deposition (CVD) process.

- Common types of glass fiber include single-mode fiber and multi-mode fiber.

- Single-mode fiber has a small core diameter (about 8-10μm), allows only one light mode to propagate, and is used for long-distance and high-speed transmission.

- Multimode optical fiber has a larger core diameter (50-100μm), can support the propagation of multiple light modes, and is suitable for medium and short distance transmission.

Transmission performance, reliability and cost of glass fiber:

- Glass optical fiber has excellent optical transmission performance and can achieve long-distance, high-bandwidth, low-loss optical transmission.

- The loss of single-mode glass optical fiber can be as low as 0.2dB/km, which is much better than plastic optical fiber.

- Glass optical fiber has high reliability and can work stably for a long time in harsh environments.

- However, the manufacturing process of glass optical fiber is more complex and the cost is relatively high.

Application of glass optical fiber in high-speed broadband network:

- Glass optical fiber is widely used in backbone networks and metropolitan area networks of telecom operators, supporting high-speed broadband services such as 5G and FTTH.

- In data centers and enterprise campus networks, glass optical fiber is also the main transmission medium, providing support for high-bandwidth applications.

- For scenarios requiring long-distance, high-bandwidth transmission, such as submarine cables and satellite communication systems, glass optical fiber is the preferred solution.

- With the development of ultra-high-speed optical networks such as 100G and 400G in the future, glass optical fiber will play an important role in more application fields.

It is not difficult to see from the above that with its excellent optical transmission performance, good reliability and continuously reducing costs, glass optical fiber has become the backbone technology of high-speed broadband networks and is widely used in telecommunications, data centers and other fields. . With the continuous innovation of optical communication technology, the application prospects of glass optical fiber will be broader in the future.

Plastic optical fiber

Let me introduce to you in detail the manufacturing process, performance characteristics and application of plastic optical fibers in special application scenarios:

Manufacturing process and material composition of plastic optical fibers:

- Plastic optical fiber is usually made of polymer materials, such as polymethylmethacrylate (PMMA).

- The manufacturing process is relatively simple, usually using extrusion molding, and the cost is low.

- The refractive index of the core material and the cladding material is different, thereby achieving the transmission of optical signals.

Advantages of plastic optical fiber:

- Plastic optical fiber has high flexibility and bending resistance, making it easy to install and wire.

- Plastic materials are tougher and more durable than glass and less likely to break.

- The production cost of plastic optical fibers is low and is conducive to large-scale application.

- Plastic optical fiber has good anti-electromagnetic interference performance and is safer.

Application scenarios of plastic optical fibers:

- Plastic optical fiber is mainly used for indoor short-distance transmission, such as home entertainment systems, automotive infotainment networks, etc.

- Due to the relatively limited transmission distance and bandwidth of plastic optical fiber, it is not suitable for backbone networks and long-distance applications.

- But in some special environments, the advantages of plastic optical fibers are more obvious, such as:

- In environments with strong electromagnetic interference, plastic optical fibers can provide better immunity to interference.

- For application scenarios that require flexible wiring and installation, plastic optical fiber is more suitable.

- In some safety-sensitive fields, the low-voltage characteristics of plastic optical fibers are also more advantageous.

In short, plastic optical fibers play an important role in short-distance transmission and special application scenarios due to their low manufacturing cost, good flexibility, and strong anti-interference ability. With the continuous advancement of technology, plastic optical fibers will also have wider application prospects in the future.

Selection of glass optical fiber and plastic optical fiber

Let me summarize the factors to consider when choosing between glass optical fiber and plastic optical fiber in practical applications:

Comparison of the differences between two optical fiber materials:

- Transmission performance: Glass optical fiber has better optical transmission performance, lower loss and larger bandwidth.

- Reliability: Glass optical fiber has higher reliability and longer service life in harsh environments.

- Cost: The manufacturing cost of plastic optical fibers is relatively low and suitable for large-scale applications.

- Mechanical properties: Plastic optical fiber has high flexibility and bending resistance.

Selection considerations for different application scenarios:

- Long-distance backbone network and high-speed broadband applications: suitable for using glass optical fiber with superior performance.

- Indoor short-distance transmission and flexible cabling applications: suitable for using lower-cost plastic optical fibers.

- Environments with strong electromagnetic interference: Plastic optical fibers have better anti-interference properties.

- Safety-sensitive areas: The low-voltage characteristics of plastic optical fibers are more advantageous.

- In situations where long-term stable and reliable operation is required: glass optical fiber is more suitable.

Best practices for fiber optic material selection:

- For applications requiring high bandwidth and long-distance transmission, glass optical fiber is preferred.

- For indoor short-distance transmission and flexible wiring scenarios, plastic optical fibers can be considered.

- In some special circumstances, plastic optical fiber or a combination of two materials can be selected according to specific needs.

- In future network planning and construction, priority should be given to the use of glass optical fiber to support ultra-high-speed transmission requirements such as 100G and 400G.

- No matter which optical fiber material is chosen, attention must be paid to compatibility with other system components to ensure the reliability and performance of the overall solution.

Therefore, glass optical fiber and plastic optical fiber each have their own applicable application scenarios. When making the actual choice, you need to weigh many factors such as performance, cost, and reliability, and make the best decision based on future network development trends.

Summary

Optical fiber is an important support for modern communication technology. Its material composition directly determines the transmission performance and application scenarios of optical fiber. Glass optical fiber is widely used in high-speed broadband networks due to its excellent transmission performance and reliability, while plastic optical fiber plays a unique role in short-distance transmission and special scenarios due to its flexibility and economy.

In practical applications, it is necessary to weigh the advantages and disadvantages of the two optical fiber materials based on network requirements, deployment environment and other factors to choose the most appropriate solution. Our professional technical team is ready to provide you with a full range of optical fiber application support. If you have any questions during the selection and use process, please feel free to contact us for communication.

Are fiber optics made of glass or plastic FAQ

Fiber optic cables are typically made of either glass or plastic.

Glass fiber optics are made from extremely pure and thin strands of glass, while plastic fiber optics use a polymer-based material.

Glass fiber optics are much more widely used for long-distance and high-speed data transmission applications than plastic fiber optics.

Glass fibers generally offer lower signal attenuation, higher bandwidth, and longer transmission distances compared to plastic fibers.

Plastic fiber optics are sometimes used in shorter-distance applications, such as in-home or industrial networking, due to their lower cost and easier handling.

Glass fiber optic cores are typically much smaller, ranging from 8-10 microns for single-mode to 50-100 microns for multi-mode, while plastic fibers are larger, around 240-1000 microns.

Glass fibers are more fragile and require more precise handling, while plastic fibers are more flexible and resistant to bending and impact damage.

Glass fibers generally offer higher bandwidth, lower signal loss, and longer transmission distances compared to plastic fibers.

No, glass and plastic fiber optics are not interchangeable and require different types of connectors and network equipment.

Glass fibers are widely used in long-distance telecommunications, internet backbones, and high-speed data centers, while plastic fibers are more common in short-range industrial, automotive, and home networking applications.